Your factory’s potential manufacturing capacity is lost to several wastage factors:

- Breakdowns: Line stoppages because of plant breakdowns.

- Setup: Stoppages due to having to perform machine set-ups between

batches. - Raw Material Stockout: Line stoppages due to unavailability or poor

quality of raw materials. - Rework: Time spent reworking defective units instead of producing units.

- Training: Time lost because of worker involvement in training or

improvement groups.

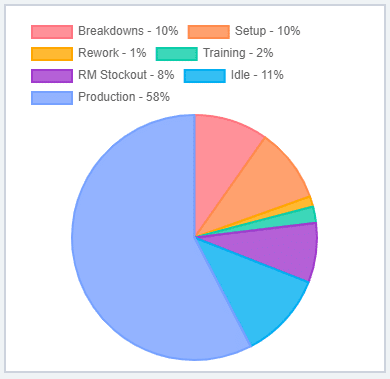

You can track maximum potential factory capacity and wastage factors through the forecast capacity usage pie chart on the right-hand side of the Capacity decision screen:

Minimizing these wastage factors will increase the “Production” percentage above, and therefore, your usable factory capacity. In general, your goal should be to achieve a production percentage of at least 80%.

Breakdowns

Breakdowns are unexpected stoppages in machinery due to mechanical failure. These cause downtime in the manufacturing process, and therefore, delays in supplying bikes to your customers.

Preventative maintenance expenditure ensures that your factory plant machinery is serviced regularly to reduce breakdowns and ensure maximum run time.

Preventative maintenance also serves to reduce the number of product defects and increase internal quality. In addition, adequate maintenance also serves to maintain the resale value of your machinery if you ever need to sell capacity.

Note that as you increase your factory capacity, more expenditure is required to maintain the same level of maintenance.

Setup

Manufacturing batch size reflects the average quantity of bikes produced in a single production run. Smaller batch sizes decrease factory lead-time and potentially delivery times, but comes at the cost of more setups.

Expenditure in setup time reduction goes into developing more efficient procedures for setting up manufacturing batches, enabling you to run smaller batch sizes and increase effective capacity. Other factors affecting the capacity lost to setups are: batch size, number of products, and product complexity.

Raw Materials Stockout

Raw materials are the components required to manufacture your bikes. Ensuring reliable raw material supplies of a consistent quality is an important issue in operating a plant. Run out of raw materials or receive materials of poor quality will put a stop to manufacturing.

Raw Materials Inventory: Problems with supply can always be overcome by carrying sufficient raw material stock as a buffer, giving you time to resolve issues or find alternative supply. In MikesBikes this is expressed in weeks of production.

Increasing Raw Materials on hand is an immediate fix for supply issues, however, you incur a warehousing and implicit financing cost when you hold raw material inventories.

Supplier Relations: If you improve your relationship with your suppliers, they will be more reliable and you will need to hold less raw material inventory.

If you improve your relationship with your suppliers, they will be more reliable and you will need to hold less raw material inventory.

In MikesBikes you have the option of investing in Supplier Relations. This improves the delivery and quality of raw materials to your factory by improving contracts with suppliers, improving communication systems between suppliers and your factory, paying incentives to suppliers and expedient transport options. Maintaining strong relationships with your suppliers will ensure supply and quality issues can be better managed over time. Keep in mind that the level of accumulated supplier relations deteriorates over time.

Firms can also choose to direct resources into improving supplier relations. This includes expenditures directed towards negotiating single source contracts, providing suppliers with forecast demands and educating suppliers in JIT and TQM techniques. It may also extend to paying supplier incentives for supplying quality products, consulting suppliers when designing new products and paying increased transportation costs for more frequent deliveries.

Rework

Product defects occur as part of the manufacturing process and correspond to internal quality issues. Defects need to returned to production to be reworked to ensure a saleable product.

You can track your company’s defect rate through your company’s Home screen and through the Quality decision screen. This is the percentage of products that have been identified as defective and requiring rework.

To reduce your company’s rework rate you will need to improve Internal Quality. A high level of internal quality is attained through:

- Motivation and training of staff;

- Maintenance of machines;

- Strong supplier relations; and

- Investment in quality systems to provide on-going monitoring at every stage of the production process.

Training

Training is important for your factory staff. Well trained staff are more skillful, and therefore, more productive. In addition, training reduces the number of defects produced so will improve your internal quality. The only downside is training has the negative impact of taking staff away from day-to-day tasks.

Training is not included in the Wastage percentage for your company because Training is an investment in improving your capabilities. But it is also time that cannot be used for production.

Idle Time

Idle time is simply the percentage of time your factory sat idle not doing one of the activities above. It’s expected that your factory may be idle for less than 10% of the year, but any more than this and you should consider decreasing your factory capacity.