The quality of your finished products is determined by both your Internal Quality decisions (which affect how many defective products you produce), and your External Quality which is what the customer actually sees after you catch some of those defective products via Inspection.

A high level of Internal Quality is attained through training of people, maintenance of machines, good supplier relations, and Quality Systems Technology. This corresponds to “quality at the source” and allows you to minimize the number of defective products you produce. ie. your Product Defect Rate (%).

External Quality (and your Quality Rating) is based on how your customers perceive your products. The more defective products that reach customers, the lower your Quality Rating.

So a high Quality Rating can be achieved either by investing in people and processes (Internal Quality) or by conducting extensive inspection to catch defects before they reach the customer.

Your Quality Rating is what you see in the Market Summary report, and this is what customers use when deciding which products to buy.

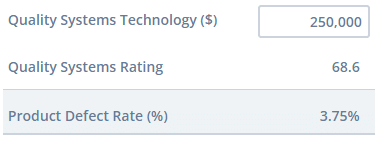

Quality Systems Technology (Internal Quality)

Investment in quality systems requires installing specialist equipment to monitor the

manufacturing process and identify product defects at the source.

This technology is expensive but is most cost-effective for high production volumes.

Note that your investment in Quality Systems Technology is relative to the size of your Factory. So if you purchase a lot of Factory Capacity, then you should expect to spend significantly more on Quality Systems Technology.

Remember to also review your Staff Training, Supplier Relations, and Preventative Maintenance to improve your Internal Quality and reduce your Product Defect Rate.

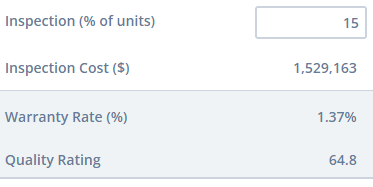

Inspection Rate (External Quality)

Once your bikes have been produced, a final quality control inspection identifies product defects before they reach the customer. Not every product is checked, but instead a sample percentage is inspected.

Keep in mind that a high inspection rate is expensive as production volumes climb. So over time it may be more cost effective to invest in Internal Quality so you can gradually reduce your Inspection Rate.

But Inspection Rate will have an immediate impact on your Quality rating, so you can choose to spend more on inspection to improve your Quality Rating in the short term.