Two reasons why your project failed:

1. The project/budget expenditure was too low and/or;

2. The requested unit prime cost was unrealistically low

As in real life, you do not want to commit to a product development project without checking that it was appropriately funded and that it would be able to provide an acceptable return on investment.

In addition, you have to be careful that the specifications you enter for your new product actually fall close to the ideal point of the segment you are targeting. Look under Reports for Perceptual Map of Market Segments to check this. Products outside the radius of influence (i.e. outside the circles) will not sell at all.

How do we conduct successful development projects?

We will walk you through an example where we develop the design for a Racers bike. While the specifics and calculations may change, the steps you follow will be the same:

1. View the Indicative Values for Market Segments within the Product Development Scenario Information report to view the ideal product attribute levels desired by each segment. (Note: These desired product attributes by each market segment change slightly from year to year so be sure to keep monitoring for the changes.)

2. Take the current Style/Tech Specs of your closest existing Design Project and calculate the required change in Style/Design and Technical Specs.

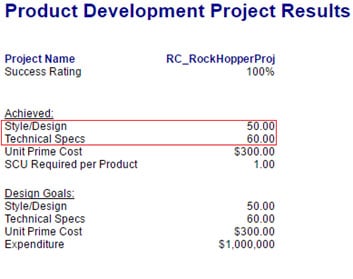

In our example, the closest existing Design Project is our Adventurer Bike. You can view the Product Development Project Results Report to view your closest existing design paying attention to the Style/Design and Technical Specs:

3. Calculate the difference in Style and Technical Specifications between the desired design and the closest existing design.

As you can see, in this example, our only and closest existing design project is our Adventurer product. This features specifications of 50 Style and 60 Technical. Our desired design project has targeted specifications of 20 Style and 86 Technical.

So the difference is 30 Style and 26 Technical.

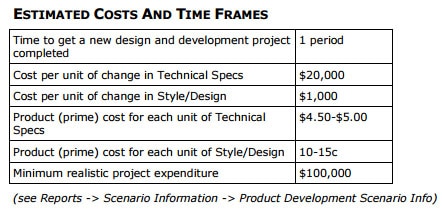

We can see on the Product Development Scenario Information report that each unit of Style development costs $1000 and each unit of Technical development costs $20,000.

Our example calculation will be:

30 x $1,000 added to 26 x $20,000 = $550,000

Therefore, our design cost would be $550,000 on the new design to achieve 20 Style and 86 echnical.

4. Calculate your prime cost.

From the table above we can see that the prime cost will be calculated at roughly $0.1 to $0.15 per design and $4.50 to $5.00 per technical specification. We want a racers bike with 20 style/design and 86 technical specifications.

A conservative calculation would therefore be:

0.15 x 20 added to 5.00 x 86 = $433

If we enter any additional expenditure on to our design cost this will be used to further reduce the Prime Cost.

Note: This does NOT mean you should always aim super low with target Prime Cost. If you aim too low, then your project won’t have enough money to achieve its objectives and you will miss your style / tech spec targets as well as your prime cost target.

How do I correct a failed product design?

A failed product design is a design that shows anything less than 100% success rate within the Product Development Results Report. Unfortunately this means you will need to design the design again. However! The failed design is likely to be a lot closer to your desired specifications than the previous closest design, thus it means it is likely to be cheaper to invest in. Simply follow the process above again working off the new closest existing design (even if the closest existing design is a failure).

Questions?

We strongly recommend all MikesBikes Advanced users view our Business Simulation Tutorial Videos.

If you have any questions just send us an email through our Contact Us page.