There are three Operations decisions that you make in the MikesBikes Introduction to Business Simulation; Factory Capacity, Efficiency and Quality.

Factory Capacity

You will be able to control your Factory Capacity in Year 2 of the simulation. Your Factory Capacity is measured in Standard Capacity Units (SCU). Your Factory’s total SCU will determine how many bikes you can produce. For example, the standard Mountain bike requires 0.5 SCU to produce one bike. So if your Factory Capacity was 20,000 SCU, you would be able to produce 40,000 bikes.

You should look to increase Factory Capacity when you expect sales of your Mountain Bike to increase, and also when you launch new products. You should look to decrease Factory Capacity if you have excess Factory Idle Time, usually caused by lower sales than expected.

Factory Efficiency

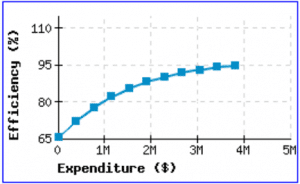

Wastage during production of your bikes is caused by time spent on setting up machinery, maintenance and breakdowns. These act as a constraint on productivity by absorbing a proportion of your Factory’s available production capacity. The Efficiency decision in MikesBikes determines the amount to be spent on reducing Wastage. The more that you can decrease Wastage, the more of your Factory Capacity will be available for production.

Important: A larger Factory will require a greater amount spent on Efficiency. Therefore, when you increase the size of your Factory, through the Capacity Planner, you will also need to increase Efficiency expenditure to maintain your existing Efficiency level.

Factory Quality

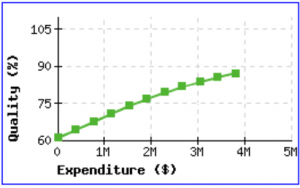

Your Factory’s quality systems will determine the build quality of your products. This is reflected in the Quality Index which can be tracked on the Market Summary report.

Quality is a key driver of demand for some of the market segments in your industry (see Market Information report). If you have a product in these markets, expenditure in Quality will be important to develop a competitive product.

Important: A larger Factory will require a greater amount spent on Quality Systems. Therefore, when you increase the size of your Factory, through the Capacity Planner, you will also need to increase Quality expenditure to maintain your existing Quality Index.

Questions?

If you have any questions just send us an email through our Contact Us page.